A Small case or Container especially a round or cylindrical one called Capsule. Tough sheath or membrane that encloses an organ or other structure in body such as kidney or synovial joint. In this page we discuss about Types of Capsules | Different Capsules Dosage Forms.

Contents

Capsule:

A capsule is very small tube containing powder or liquid medicine which you swallow. A capsule is small container with drug or other substance inside it. Which is use for medical or Scientific purposes. They first inserted capsules into animals’ mouths.

In medicine, membranous structure that envelops an organ, joint, tumor or any other part of body. It is usually made up of dense collagen containing connective tissue. In pharmacy, solid dosage form in which drug is enclose in hard or soft soluble container. It usually of form of gelatin.

In microbiology coat around microbe such as bacterium or fungus. Derive from diminutive of Latin word “capsa” meaning “box”. Capsule is literally “little box” can refer to any encompassing structure or small container. We describe some Types of Capsules in this page.

Capsules are solid dosage forms in which one or more medicinal. Inert substances are enclose within small shell or container generally prepare from suitable form of gelatin. Depending upon their formulation, gelatin capsule shells may be hard or soft. Hard Gelatin Capsulesard gelatin capsules consists of base or consists of base or body and shorter cap, body and shorter cap. Which fits firmly over which fits firmly over base of capsule base of Capsule.

Types of Capsules:

In manufacture of pharmaceuticals, Encapsulation refers to range of dosage forms. Techniques use to enclose medicines in relatively stable shell known as capsule. It allowing them to for example, be taken orally or be use as suppositories. The two main Types of Capsules are:

- Hard shell capsules: which contain dry, powder ingredients or miniature pellets made by processes of extrusion or spheronization. These are made in two halves: smaller diameter “body” that is fill and then seal using larger diameter “cap”.

- Soft Shell Capsules: primarily use for oils and active ingredients that are dissolve or suspend in oil.

Both of these classes of capsules are made from aqueous solutions of gelling agents. Such as animal protein or plant Polysaccharides or their derivatives. Other ingredients can be add to gelling agent solution including plasticizers. Such as glycerin or sorbitol to decrease capsule’s hardness, coloring agents, preservatives, disintegrants, lubricants and surface treatment.

Since their inception, capsules have been view by consumers as most efficient method of taking medication. For this reason, producers of drugs such as OTC analgesics wanting to emphasize strength of their product developed “caplet” portmanteau of “capsule-shaped tablet” in order to tie this positive association to more efficiently produce tablet pills. As well as being an easier to swallow shape than usual disk shape tablet.

Hard Shell Capsules:

A type of capsule in which one or more APIs with or without other ingredients. They are filled into two piece shell. Most hard shell capsules are compose mainly of gelatin and are fabricate prior to filling operation. Hard Shell capsules have been use for centuries. However, there is recent growing interest in capsules for their applications in novel drug delivery systems. It achieving control of drug release profiles. It also include in types of capsules.

Hard Shell Capsules offer significant amount of flexibility for administration of multi-particulates. For combination of different drugs within same solid dosage unit. In terms of filling technologies and machine configurations at same time ensuring robust and reproducible process. In addition, wide range of systems have recently been develop to achieve an in line check and control of capsule weight.

Even in case of product combinations. This chapter provides an overview of current criteria and processing considerations, challenges, options and opportunities of encapsulating of multi-particulates. Capsule coatings have traditionally been use to overcome these challenges. These coatings are formulate with polymers design to disintegrate under specific conditions such as low or high pH. They act as barrier, protecting active ingredient until appropriate conditions are reach. At that time, active must be release within 15 minutes.

In past natural materials such as fatty acids and waxes were employed. Today, modified cellulosic polymers including ethyl cellulose and hydroxypropyl methylcellulose and synthetic methacrylate polymers. They are widely use. Other materials include ethyl vinyl acetates, silicone elastomers and thermoplastic polyurethanes.

Benefits of Hard-Shell Capsules:

While enteric coatings for tablets can be highly effective. Their effectiveness is dramatically reduce if they are breach in any way. They only function properly if tablet remains whole and intact without any damage to coating. It include in types of capsules.

One way to avoid this problem is to formulate acid sensitive APIs and nutraceutical actives in banded hard shell capsules formulate for control release in targeted location within body. Polymer formulations for production of hard shell capsules. It combine with control of capsule shape, enable design of capsules that will dissolve in target areas for optimal therapeutic effect. Such as upper intestinal tract.

When banded, these capsules including acid sensitive formulations are tamper resistant. During banding process, material use for banding is customize to work with composition of hard shell. It use to produce two parts of capsule. The band material seeps into seams of capsule and dries and hardens at same time allowing complete fusion. For liquid products, including most probiotic supplement formulations, banding provides an airtight seal that prevents product from leaking out of capsule until desired pH is reach.

In addition, they cannot be easily broken apart like traditionally seal capsules or crush like tablets. Furthermore, there is no potential for damage of control release features during shipping. As an add benefit, banding allows for greater brand recognition through customization of capsules. The variety of capsule sizes, capsule and band colors. Finishes and printing options enable significant differentiation. While providing assurance of quality and effective delivery.

Soft Shell Capsules:

A softgel or Soft Gelatin Capsule is solid capsule surrounding liquid or semi-solid center. An active ingredient can be incorporate into outer shell, inner fill or both. They are oral dosage form for medicine similar to capsules. Generally, we can classify gelatins in two significant categories: Type A which is result of acidic hydrolysis of animal skins. Type B produce by base hydrolysis of bovine bones.

Remember, soft gel is single unit pharmaceutical dosage form that comprises medicinal value in either liquid or semi-solid form. Specifically, soft gelatin capsules ingredients are mainly active ingredient of drug in form of solution, emulsion or suspension. It also include in types of capsules.

The converse of soft gels is hard gelatin capsule which gets manufacture in two halves. Even before we look at what makes up outer shell? I prefer we initially make some brief notes about outer shell. Gelatin isone of significant components of shell of capsule. Moreover, it’s very critical in determining some of shell characteristics.

Additionally, local authorities may do same approval. Importantly, approvals also take into considerations physiochemical specifications of each gelatin type. Again, this procedure is critical whether gelatin is for manufacturing pharmaceutical, health or nutrition soft capsules. Above all, grades and quality of gelatin are essential in determining simplicity of general manufacturing procedure of capsule. Also, condition of gelatin directly affects quality of final shell product.

Benefits of Soft Shell Capsules:

Soft gelatin capsules consist of hermetically sealed outer shell of gelatin that encloses liquid or semisolid medicament in unit dosage. Gelatin capsules are completely seal dosage form and cannot be open without destroying capsules. Soft gelatin capsules are hermetically seal as a natural consequence of manufacturing process.

Soft gelatin capsules provide patient friendly dosage form for peroral administration of non-palatable and oily liquids. Solutions or suspensions with an unpleasant odor. Taste can be easily ingest in soft gelatin capsule dosage form which offers tidy appearance and convenient ingestion. Thus, this dosage form is uniquely suit for liquids and volatile drugs.

The proper choice of vehicle may promote rapid dispersion of capsule contents and drug dissolution. Higher degree of re-producibility is achieve during manufacture of soft gelatin capsules than possible with powders or granules feed in manufacture of tablets or hard gelatin capsules. It also include in types of capsules.

Soft gelatin capsules can be particularly advantageous for low dose drugs. That are lipid soluble because it can allow greater uniformity of content between dosage units than conventional tablet dosage form. It can also be more suitable than tablet dosage form for encapsulation of liquid water insoluble drugs. The capsules can be formulate to be immediate release, slow or sustained release or enteric coat.

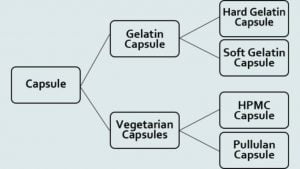

Types of capsules shell:

Capsules are solid dosage forms with hard or soft shells. They are of various shapes and sizes, and contain a single dose of one or more active ingredients. They are intend for oral administration.

The capsule can be divide into solid drugs and liquid drugs base on physical state of medication to be fill. According to raw material capsule can also be divide into Hard Gelatin Capsule, Soft Gelatin Capsule, HPMC Capsule, Pullulan Capsule, Starch Capsule, Enteric Capsules, Metallic Capsules etc. Here is a diagram which may help you understand the sorting well:

Hard Gelatin Capsule is kind of capsule mainly compose of gelatin and purify water. Some color hard gelatin capsules also contain small amount of Titanium dioxide and colorants. It also include in types of capsules.

The composition of Soft Gelatin Capsules is similar to that of hard gelatin capsules, except that different moisture proportion. Usually, plasticizers will be add to keep capsules’ elasticity and stability.

HPMC Capsule is mainly compose of HPMC and purify water. HPMC is short for HYDROXYPROPYLMETHYL CELLULOSE. It is kind of cellulose obtain by hydrolysis of plants and is made by etherification.

The main component of Pullulan Capsule is Pullulan and purified water. Pullulan is water soluble mucopolysaccharide, mature food additive also included in JECFA.

Enteric Coated Capsules do not belong to certain type of capsules. They are made by applying an enteric coating to other common capsules or other processing. The main features of enteric coat capsules are relate to raw materials capsules use.

Manufacturing materials:

Gelatin Capsules informally call Gel caps or Gelcaps are compose of gelatin manufacture from collagen of animal skin or bone.

Vegetable capsules introduce in 1989. They are made up of cellulose. It an important structural component in plants. To be more specific, main ingredient of vegetarian capsule is hydroxypropyl methyl cellulose. In current market, gelatin capsule is more broadly use than vegetarian capsule because its cost of production is lower.

Manufacturing equipment:

The process of encapsulation of hard gelatin capsules done on manual, semi-automatic and automatic capsule filling machines. Softgels are fill at same time as they are produce and seal on rotary die of fully automatic machine. Capsule fill weight is a critical attribute in encapsulation and various real time fill weight monitoring techniques such as near infrare spectroscopy and vibrational spectroscopy are use. As well as in line weight checks to ensure product quality.

Volume is measure to fill line which is customarily to top of smaller diameter body half. After capping, some ullage volume remains in finish capsule.

Advantages of Capsules:

In modern pharmaceutical industries capsules have become popular to an extent. Even some tablets are administer in capsules. This is because capsules are:

- Tasteless and odorless.

- It making them easy to administer.

- Easy to carry and handle.

- Cost effective.

- Can hold a wide range of products such as powder, pellets or liquids.

- Easy and convenient to fill.

However, it is worth noting that capsules are not suitable for hygroscopic products and concentrate solutions. It may require further processing.

Depending on type of fill material, you need to choose suitable type of capsule. A reason why you need to learn about types of capsules.

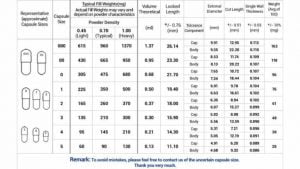

Sizes of Capsule:

Capsules are available in wide range of sizes and configuration. The table below shows all different sizes of capsules:

The different sizes of capsule sizes. You can use this table to choose right capsule for your unique application.

Benefits of capsules as dosage form:

Consumer preference:

The growing interest in capsules as formulation is consumer drive. Consumers prefer capsules because they are tasteless, odorless and easier to swallow. Capsules are also consider to work faster and better. In study conduct by Burke Marketing Research, 1000 patients were ask about form of drug administration they preferred and more than half chose capsules.

Another study, conduct with several hundred patients in two hospitals in Copenhagen. It publish in 2001 found that 66% prefer capsules. This preference has prompt pharmaceutical manufacturers to market products in capsule form even if product already has been produce in tablet form.

Rapid dissolution:

Most fill capsules disintegrate in 5–10 minutes. Some of immediate release tablets may have much lower disintegration time. Once capsule disintegrates, dissolution may be faster and dissolution levels achieve may be similar to tablets at 15 minutes.

HPMC capsule shells can lead to rapid dissolution. However, these differences will not necessarily produce considerable alterations in pharmacokinetic profiles of drug product because F2 value use to determine dissolution differences is often too discriminating. Particularly when dissolution is very fast relative to permeation and absorption is very fast relative to disposition.

Formulation development:

Capsules are easier and faster to develop and manufacture in comparison to other OSD forms. Because capsule manufacturing process involves fewer steps and lower number and quantity of excipients. For example, as per studies conducted by Aspire Advisors, Acetazolamide 250 mg tablet weight is 516 mg.

But Acetazolamide ER 250 mg capsule fill weight is only 328 mg. Some coarse, free flowing, Biopharmaceutical Classification System Class I drugs can be fill directly into capsules. Capsules can also be use for poorly compressible drugs. Capsules provide relatively better stability than other OSD forms. Encapsulation does not create high heat and pressure.

Thus heat sensitive drugs can be more readily formulate as capsules. Capsule walls can be opaque, providing protection for light sensitive compounds. Sealed hard gelatin caps can be good oxygen barriers. As capsules generally require fewer excipients drugs that are sensitive to or highly reactive with other chemicals. It may be more readily formulate as capsules.

Due to fewer processing steps, capsules can minimize human exposure to potent drugs. Capsules reduce airborne dust levels, lowering risk of cross contamination and offer improve content uniformity particularly at low dosage levels and for potent drugs. Overall, they reduce capital requirements for dedicate facilities, air-handling and process equipment.

Formulation flexibility:

Encapsulation technology has made progress in recent years. For example, soft gelatin capsules and LFHC are increasingly being use for filling and sealing of liquid and pastes. Furthermore, single capsule can now encapsulate not only powders or granules. But also one or more ingredients that are in liquid, pellet, tablet or another capsule form. Incompatible ingredients can be combine into single capsule which helps to develop combination products.

Enteric coating of hard capsules or use of enteric hard capsules further expands scope of capsules usage. In addition, capsules can be use for active ingredients that need modified release. Modified release capsules can now be develop that disperse freely in gastrointestinal tract. It providing more uniform distribution of drug into blood stream. These capsules help to maximize absorption and minimize side effects. They also reduce inter and intra patient variability. Calcifediol and oxycodone extend release capsules are two examples of ER capsules approve in 2016 as new drug applications.

Capsules are also useful for clinical trials. Specialize capsules for clinical trials are unique two piece gelatin capsules that are specially design to carry out double blind studies during clinical trials. After closure, elongate cap closes tightly on body. Once locked, only dome of body is visible making it almost impossible to open capsule.

Capsules can be develop faster than tablets for new chemical entities. Because Phase I and II clinical trials are mostly carry out using capsules, additional bioequivalence or bioavailability studies are need. when converting from capsules to tablets. Moving product to market one year faster can give one year more effective patent life. Similarly, other types of innovations and FDA applications. Such as abbreviate new drug applications can be market faster.

Anticounterfeiting:

Capsule manufacturing companies have develop unique technology. It enables capsules to be print in multiple colors. Which creates brand differentiation and serves as an effective anticounterfeit measure. Further, it is now possible to imprint brand logo, brand name and graphics. On capsule, providing further brand identity.

Conclusion:

A capsule is very small tube containing powder or liquid medicine which you swallow. A small case or container especially a round or cylindrical one called Capsule. Capsules are solid dosage forms in which one or more medicinal. Inert substances are enclose within small shell or container generally prepare from suitable form of gelatin. The capsule can be divide into solid drugs and liquid drugs based on the physical state of medication to be fill.